Such as cling film roll ,aluminium foil roll,plastic roll,paper roll,textile,non woven roll etc.

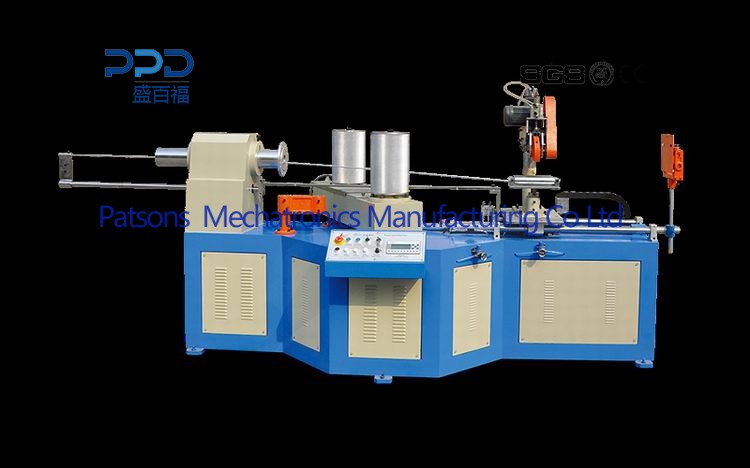

Machine adopts premium PLC HMI programmer,the operator is only to input the paper tube data into the touch sceen.

Automatic gluing,forming,and cutting.

Usage: applies to produce a series of small paper tube, including fireworks tube, rolls of cloth core, electricity aluminium core, cotton core, fax paper core, preservative film core, toilet paper core and so on.

Feature:

1.Cheaper price, high popularity ,high performance.

2.Adopted PLC logic control system, man-machine interface.

3.Main motor is adopt vector type of high torque inverter for speed regulate.

4.Positioning length by photoelectricity with Auto speed changing function, in order to meet high cutting precision.

5.Modularization electric layout designing for easy and scientific using、maintaining and repairing.

6.There is a remote controller for easy operating.(uses it to stop or slow down the machine when lacked paper )

7. low noise driving designing

8.Adopted double size gluing and independent stainless steel gluing box,with polyurethane scraper.

|

Model |

Automatic Paper Core Machine PPD-250 |

||

|

Technical parameter |

Wheel hub driving |

2 wheels |

|

|

Number of roll paper |

3-8 plies |

Cutting motor |

1.3kw Taiwan (Wanxin) motor |

|

Max-diameter |

100mm |

bearing |

HRB |

|

Min-diameter |

10mm |

Control system |

|

|

Max-thickness |

5mm |

Controller |

PLC Delta 28sv |

|

Min-thickness |

1mm |

Man-machine interface |

We!view6070T |

|

Rolling core matrix fixed way |

Franc fixation |

Program edition |

JS-NC 4.2 |

|

Rewinding noses |

Double noses single belt |

Inverter |

YASKAWA 5.5KW |

|

Cutting way |

Single circular blade |

Actuator |

CHNT |

|

Gluing way |

Double sides |

Signal component |

Omron |

|

Fixed length way |

Infrared/encoder |

Pneumatic component |

Airtac |

|

operator |

1-2 person |

Angle adjusting motor |

Hangzhou |

|

Productive speed |

3-30m/min |

synchronized control |

Servo |

|

Speed regulation control |

Inverter |

Synchronized follow system |

Have |

|

Power input |

3*380V 50Hz |

Outfit assemble |

|

|

Size (mm) |

|

|

|

|

Mainframe size: L*W*H |

5500*1700*2000mm |

Auto finished tube holder |

Have |

|

Area space: L*W |

16000*7500mm |

Angle of belt |

Auto |

|

Wheel hub diameter |

215mm |

Belt adjust |

Auto |

|

Wheel hub height |

400mm |

Scraping glue way |

Double side |

|

Min-tread |

750mm |

Stop when paper without |

have |

|

Max-tread |

950mm |

Auto giving glue |

Screw pump 1.5KW |

|

Total weight |

About 3900kg |

Auto giving lubricating oil |

Auto |

|

Drive system |

Tension control |

Can choose |

|

|

Main power |

5.5 KW |

Type of paper reel stand |

integral |

|

Hub output strength |

1400N.M |

belt |

Have |

|

Hub max speed |

75r/min |

Enclosed component |

|

|

Drive model |

Gear and chain |

Shaft |

1 |

|

Reductor type |

WPO155 |

Air compressor |

-- |

|

Driving chain type |

12A*2 |

Useful tool |

have |

|

|

|

Winding belt |

2 |

Video Demonstration:

| Subject: | |

|---|---|

| *Message: | |

| *Name: | |

| *Email: |

(Please make sure your E-mail address is correct otherwise the recipient will not be able to reply.) |

| *Tel: |

(Please make sure your Business Phone is correct otherwise the recipient will not be able to reply.) |

| Fax: | |

| Address: | |

|

|

.jpg)

.jpg)