Suitable Product:Glutathione oral film,oral dissolving film,nicotine oral film,ODF dietary supplement film,vitamin oral film,caffeine energy oral strips,breath strips,mouth fresh strips,tadalafil

oral dissolve film,fresh breath oral strips for dogs & cats,ondansetron oral dissolving film,oral dissolving film, memantine hydrochloride oral dissolving film,montelukast sodium oral dissolving film etc.

I、Glutathione Oral Film Coating Machine

Glutathione oral film coating machine transports or introduces the stirred and defoamed oral dissolving film liquid into the coating machine "oral dissolving film liquid tank" to start film making.

The film making process is as follows:

Start the machine→ The bottom release film (under the liquid tank) moves forward, driving the liquid medicine, and is coated by the scraper (controlling the gap between the upper scraper and

the lower bottom roller) → The release film enters the oven with the oral dissolving film slurry (control of temperature, air volume and wind speed) → Dry to the required dryness → Longitudinal

slitting (such as the coating width of 260mm, divided into 3 equal parts, more than 80 widths) → Rewinding into oral dissolving film rolls.

Features:

1. PLC programmable controller and servo technology are used to control the operation of the whole machine;

2. The bottom support paper (film) is pulled and driven by servo, with high precision and stable operation;

3.The film roll rewinding adopts an adaptive slip method, and the tension of large and small rolls is stable and easy to operate.

4. Machine adopts independent oven (hot air circulation drying): segmented temperature control is adjustable.

5. Machine adopts precision coating roller coating metering.

Main Data:

Name: Glutathione Oral Film Coating Machine

Model: PPD-OTFM320

Coating width: Maximum 320mm,

Coating thickness: 0.02-0.1mm adjustable

Coating speed: 0.01-1m/min (depending on different products)

Base material width: 350mm, OD≤300mm, paper tube inner diameter 76.2mm

Voltage: 220V, 50Hz

Power: motor 2kw, heating 24kw

Gas consumption: ≥30m3/h (self-provided), pressure: 0.6-0.8Mpa

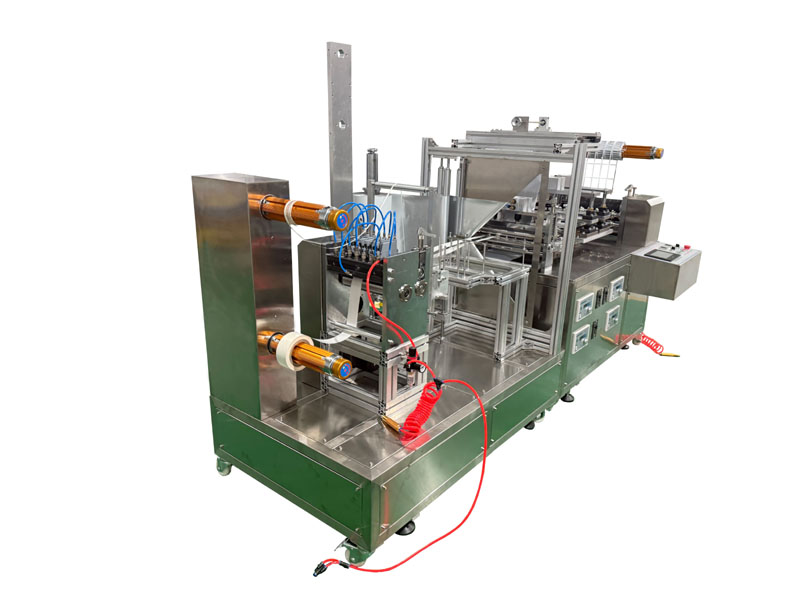

Glutathione oral film packaging machine loads the rolled oral dissolving film coil onto the "oral dissolving film coil fixed shaft" of the packaging machine.

The packaging process is as follows:

Peel off the bottom release film on the orodissolving film roll → Cut the orodissolving film longitudinally: into the required product width, such as cutting into 20mm width → then cut the length 30mm

horizontally, the cut orodissolving film sheet size is 20*30mm → the orodissolving film sheet enters the packaging film → automatic "bag making and sealing" → convey the packaged orodissolving film.

Features:

1. Uniquely designed bag making mechanism: can produce packaging bags with text patterns on both sides of the packaging bag.

2. Uniquely designed film sheet feeding mechanism: the orodissolving film sheet enters the packaging bag directly after slicing, which is stable and reliable, avoiding problems in the re-transfer process

3. Scientific and stable heat sealing mechanism: continuous, flat pressure, reciprocating operation. The heat sealing time is adjustable, which makes → the heat sealing effect better; the material and

thickness of the packaging material are more adaptable.

4. The whole machine design is directly visualized, and the mechanical structure is clear at a glance: maintenance is simple5. The PLC programmable controller and the new technology software system core developed by our factory are used to control the operation of the whole machine; feeding, film pulling, heat sealing

operation, and bag cutting are all driven by servo, with high bag making accuracy and stable operation.

6. It has its own orally dissolving film longitudinal slitting system, which can be slitting online.Main Data:

Name: Glutathione Oral Film Packaging Machine

Model: PPD-ODFP120

Film size: L:30 mm × W:25 mm or customized size

Bag size: L:85 mm × W:45 mm or customized size

Processing capacity: 120-160 bags/min

Packaging film material: Easy-to-peel film and other heat-sealable composite packaging film, OD≤320mm, width≤400mm

Voltage: 220V 50Hz

Power:motor 4kw, heating 3kw

Air supply: 0.6-0.8Mpa

| Subject: | |

|---|---|

| *Message: | |

| *Name: | |

| *Email: |

(Please make sure your E-mail address is correct otherwise the recipient will not be able to reply.) |

| *Tel: |

(Please make sure your Business Phone is correct otherwise the recipient will not be able to reply.) |

| Fax: | |

| Address: | |

|

|