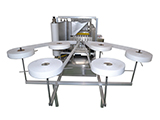

Automatic plaster forming machine can complete one-time drip injection and molding, reduce manual links,

have a higher degree of automation, and greatly improve production efficiency, and is suitable for mass

production of traditional plaster.

The machine adopts a constant tension control system, the tape runs smoothly during the strip coating process,

the material is extruded under vacuum, and the control accuracy of the amount of material is high.

Features:

1. Constant temperature heating, the medicine tank is heated by constant temperature oil or water, which is

suitable for the production of different materials and different matrix plasters, the scope of use is increased,

and the number of equipment is reduced;

2. Integrated design, high efficiency, reduce operators and reduce production process;3. Magnetic powder braking, constant tension automatic control;

4. Human-machine interface and touch screen make the positioning operation of the product easier;

5. Small footprint, simple operation, easy conversion of product specifications.

Technical parameter:

Name:Automatic Plaster Forming Machine

Model:PPD-PFM50

Speed : 50-200 pieces/min

System maximum power: 5KW

System rated working pressure: 0.6MPa

Supply pressure demand: greater than 0.6MPa

Power supply voltage: AC 380 V, 50Hz

Weight: 750kg

Dimensions: 2300x1130x1700mm(LxWxH)

| Subject: | |

|---|---|

| *Message: | |

| *Name: | |

| *Email: |

(Please make sure your E-mail address is correct otherwise the recipient will not be able to reply.) |

| *Tel: |

(Please make sure your Business Phone is correct otherwise the recipient will not be able to reply.) |

| Fax: | |

| Address: | |

|

|