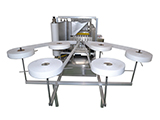

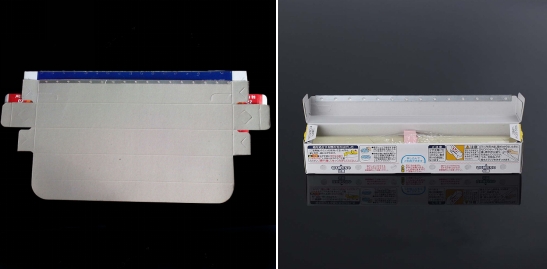

Automatic cling film saw blade binding machine(3 in 1) is a multi-functional model that integrates the punching and binding of tinplate rolls, plastic rolls, and plastic saw blades.

Machine adopts touch screen operation, PLC control, servo feeding, high degree of automation and simple operation.

Features:

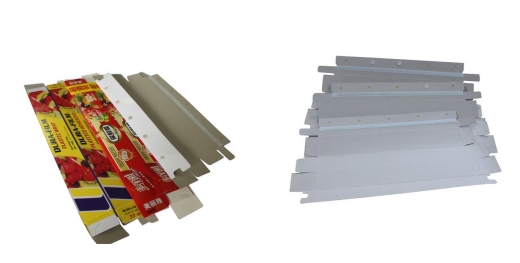

1. The color box paperboard is automatically divided and conveyed, and the paperboard is conveyed from the bottom in turn. Manually add materials from the top of the storage bin, and the paperboard can be automatically added without stopping.

2. The conveyor cooperates with the dividing device to automatically convey the paperboard, guide and position the paperboard for precise positioning.

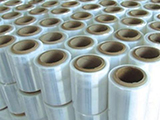

3. The raw material roll of the tinplate saw blade is automatically fed through the feeder.

4. The hydraulic power drives the mold to punch up and down, and at the same time, the tinplate saw blade is bound to the required position on the color box paperboard.

5. Automatic sensing device, the color box paper is automatically sensed by the photoelectric counting to spray hot melt glue during the conveying process.

6. The plastic saw blade in the storage bin is grabbed by the manipulator and automatically attached to the required position of the color box paper.

Main Data:

Name: Automatic Cling Film Saw Blade Binding Machine (3 IN 1)

Model: PPD-MBPP80

Applicable materials: tinplate roll, aluminum roll, stainless steel roll, PVC roll, fiber paper roll, plastic saw blade

Saw blade length: 300-450mm

Saw blade width: 8-14mm

Speed: 30-80pcs/min

Carton size (excluding tongue): L: 300-460mm* W: 235-330mm (or customized)

Voltage: 380V, 50hz

Total power: 4kw

NOTE: Different specs can be customized.

| Subject: | |

|---|---|

| *Message: | |

| *Name: | |

| *Email: |

(Please make sure your E-mail address is correct otherwise the recipient will not be able to reply.) |

| *Tel: |

(Please make sure your Business Phone is correct otherwise the recipient will not be able to reply.) |

| Fax: | |

| Address: | |

|

|